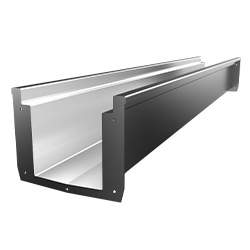

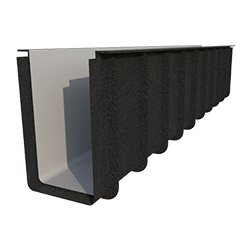

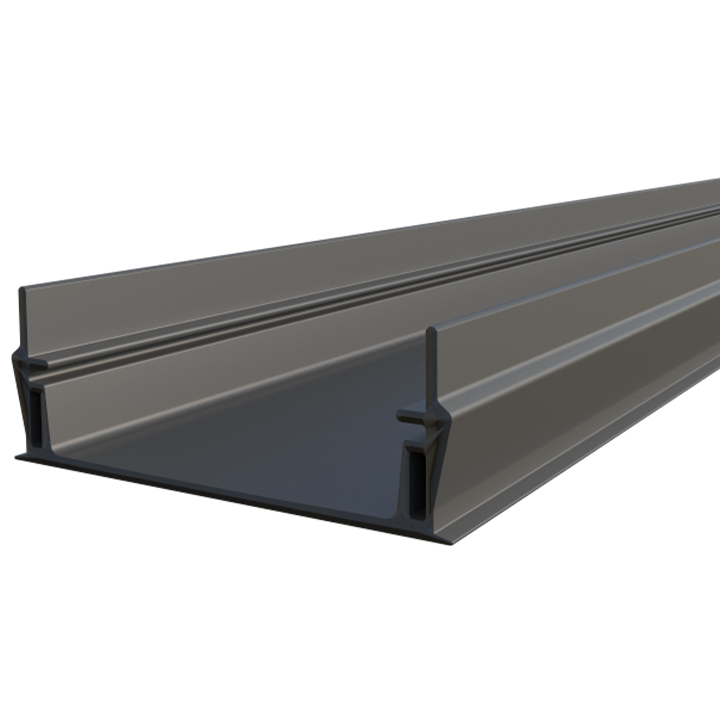

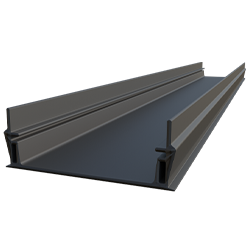

PULTRUSION CHANNEL

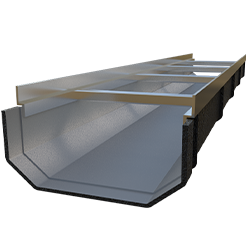

Pultrusion drainage channels are constructed with fiber-reinforced composites and provide high strength, corrosion resistance, and low weight. Suitable for chemical plants, industrial facilities, and coastal regions with extreme environmental conditions.

- Material: pulling fiber-reinforced polymers (FRP), typically glass fiber (GRP) or carbon fiber, through a resin bath and heated die.

- Color: Gray

- Usage: Used where metal or concrete channels may fail due to corrosion or weight limitations.

- Color Availability: Black

Feature

- Corrosion-resistant—appropriate for acids, salts, and chemicals in industry.

- Lightweight—less weighty to handle and fit together than metal or concrete.

- Non-magnetic and non-conductive—perfect for electrical or sensitive installations.

- Robust and abrasion resistant—resists heavy loads with little care.

- Resistant to weathering, thermal cycling, and UV.

Application

- Chemical plants and refineries—where drainage systems are exposed to aggressive substances.

- Power stations and substations—where non-conductive drainage is required.

- Marine and coastal infrastructure—resistant to saltwater and humidity.

- Pharmaceutical and food processing industries—for hygienic and corrosion-resistant drainage.

- Mining and wastewater facilities—exposed to abrasive and acidic runoff.

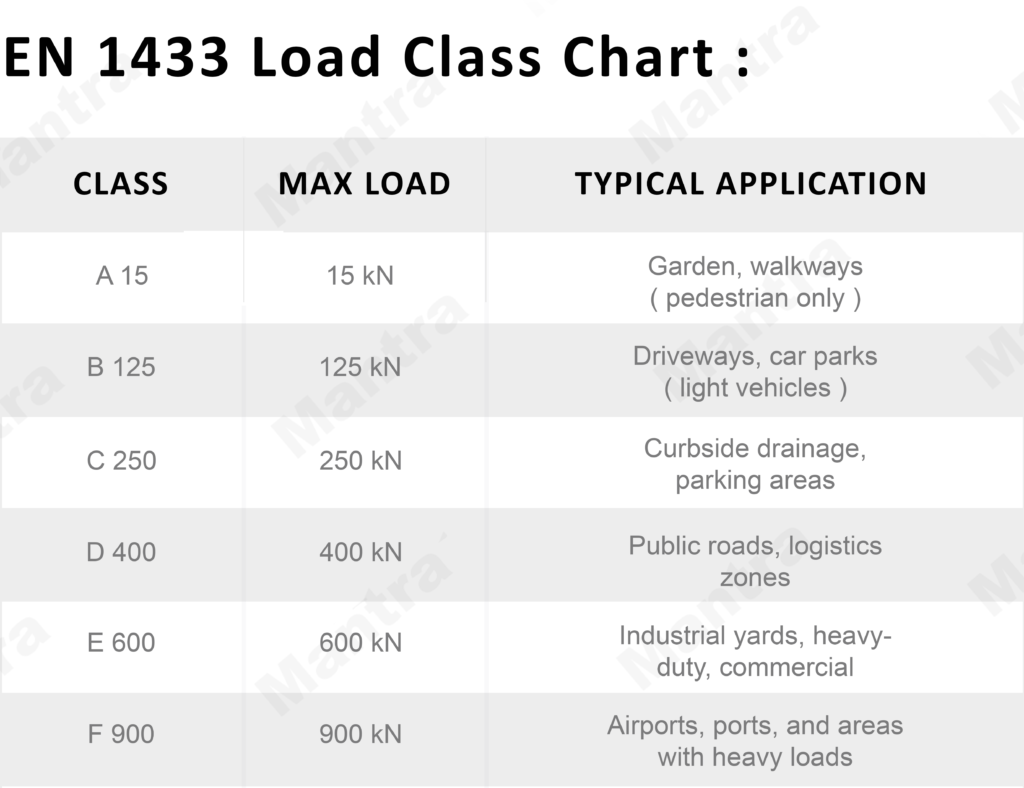

Standard Guidlines

- EN 1433 Drainage Channels for Vehicular and Pedestrian Areas (Europe)

- ASME A112.6.3 Floor and Trench Drains (U.S.)

- ASTM A240 Stainless steel material specification (for SS drain channels).

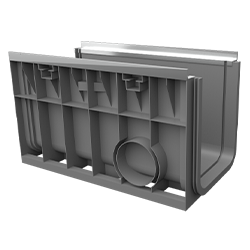

PULTRUSION CHANNEL

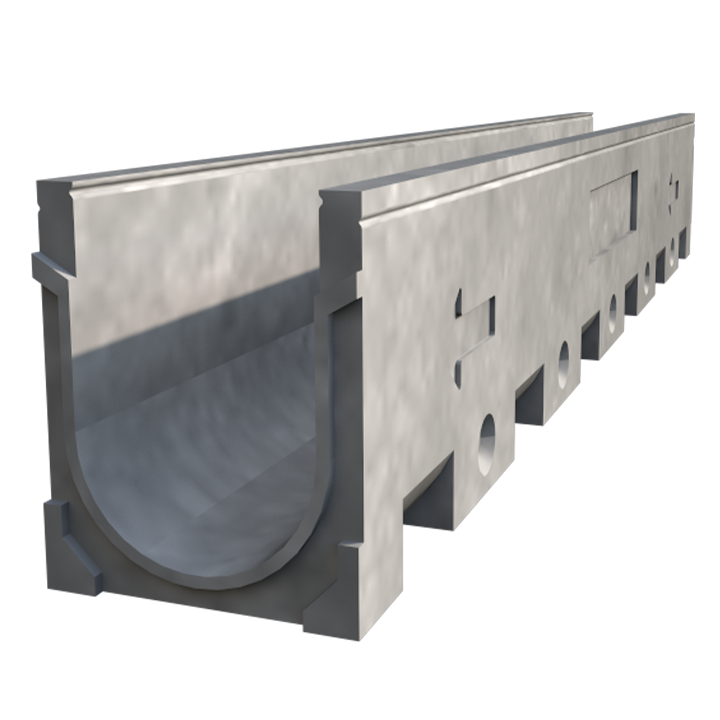

FRP CHANNEL